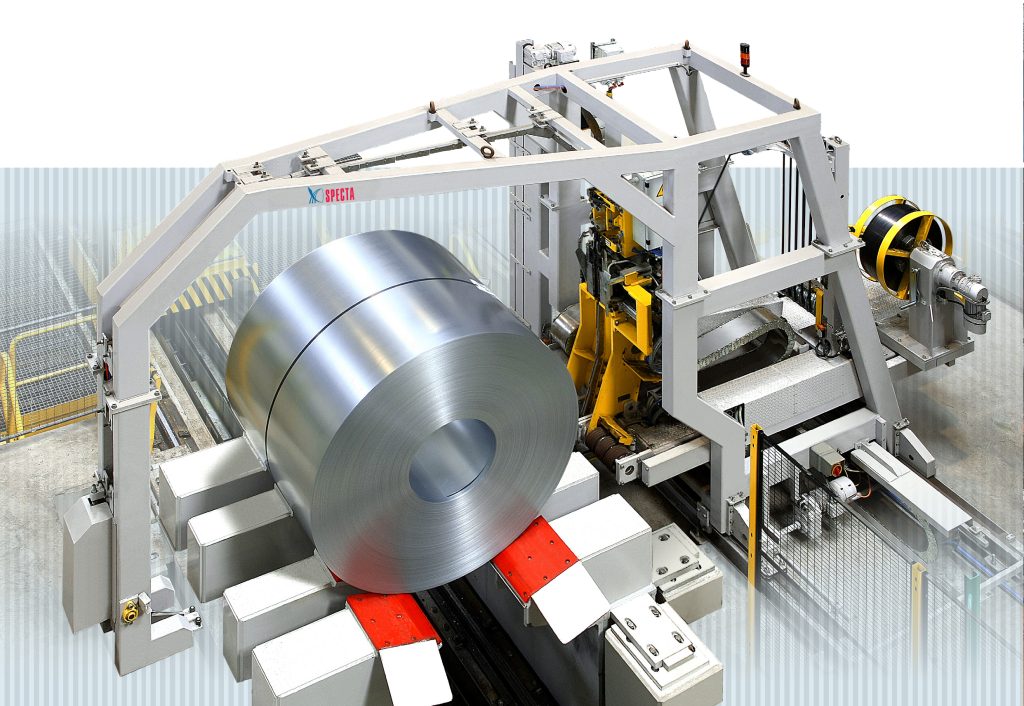

AUTOMATIC STEEL STRAPPING EQUIPMENT

Product description

AUTOMATIC STEEL STRAPPING EQUIPMENT

Automatic steel strapping machines are used for packaging heavy and oversized loads that require maximum strength and rigidity. These systems are optimal for metallurgical, woodworking, and construction industries, where strapping must endure high loads during transport and extended storage.

Key Specifications:

| Parameter | Value |

| Packaging Type | Automatic steel strapping |

| Performance | Up to 40 packages/hour |

| Strap Width | 12–32 mm |

| Max Tension | Up to 20,000 N |

| Strap Joining Methods | Notched, Sealed, or Welded |

| Strapping Formats | Vertical / Horizontal |

| Automation Level | Full |

| Control | Operator panel, PLC, touch screen |

| Line Integration | Yes, with roller conveyors and transport systems |

| Durability | High wear resistance and longevity |

Advantages of Steel Strapping:

- Maximum strength and packaging rigidity

- Reliable fixation for heavy, sharp, or hot loads

- Resistance to high mechanical stresses

- Long-lasting connections under harsh storage conditions

- Customization for non-standard product sizes

Specta supplies and installs automatic steel strapping systems manufactured in Europe and Asia.

For detailed technical specifications, pricing, and delivery times, please contact a Specta specialist.

*Please note: Specta provides on-site setup and commissioning services for automatic equipment.